Juranko S.M. d.o.o. offers the waterjet cutting system for different kinds of materials (panels), dimensions 2 m x 1 m. By using the waterjet cutting system, you optimise manufacturing expenses, and the machine, with its high level of mechanical quality and extreme precision, also makes the most complicated forms with maximum accuracy.

A waterjet cutting machine can cut metal, or any other material, by using high water pressure (2000 - 4100 bar), and fine granite sand (abrasive).

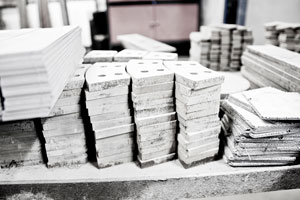

It is often used for making machine parts, components and parts of various appliances.

It is used in different industries, from mines to astronautics.

Advantages of waterjet cutting:

- processing all kinds of materials (non ferrous, aluminium and copper (materials with thermal conductivity), processing reflecting materials)

- no heating of the material-cold processing

- can process material up to 150 mm thickness

- cut with a tolerance of +/- 0,02 mm

- improved power efficiency

- no need for initial bore to start processing

- low shear stress during processing

- practically no need for clamps when positioning and securing the workpiece

- simple maintenance

- low water consumption (3,8l / min)

- max. cutting sped is 12.000 mm / min